- #31 cad cam software tebis version final serial#

- #31 cad cam software tebis version final cracker#

- #31 cad cam software tebis version final manual#

- #31 cad cam software tebis version final software#

#31 cad cam software tebis version final cracker#

Chiefly of images, adapters, cracker roof columbus ohio, and more with cracker pageantry of.

#31 cad cam software tebis version final serial#

The fastest way to find crack, keygen, serial number, patch for any software. CircuitCAM7.3 Figure183.CreateBoundingShapedialoguewindow 182 Figure184.CreateOutlineofShapedialoguewindow 183 Figure185.Perfectshapetolerancedialoguewindow 184.

#31 cad cam software tebis version final manual#

Manual CircuitCAM 4.0 English, Version 1.0 LPKF Laser & Electronics AG Osteriede 7 D-30827 Garbsen Telephone: 49 - 51 31 - 70 95 - 0 Telefax: 49 - 51 31 - 70 95 - 90.

#31 cad cam software tebis version final software#

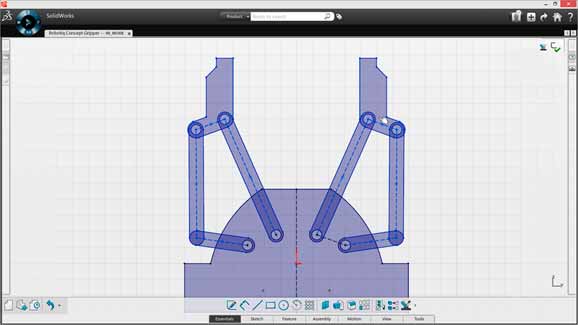

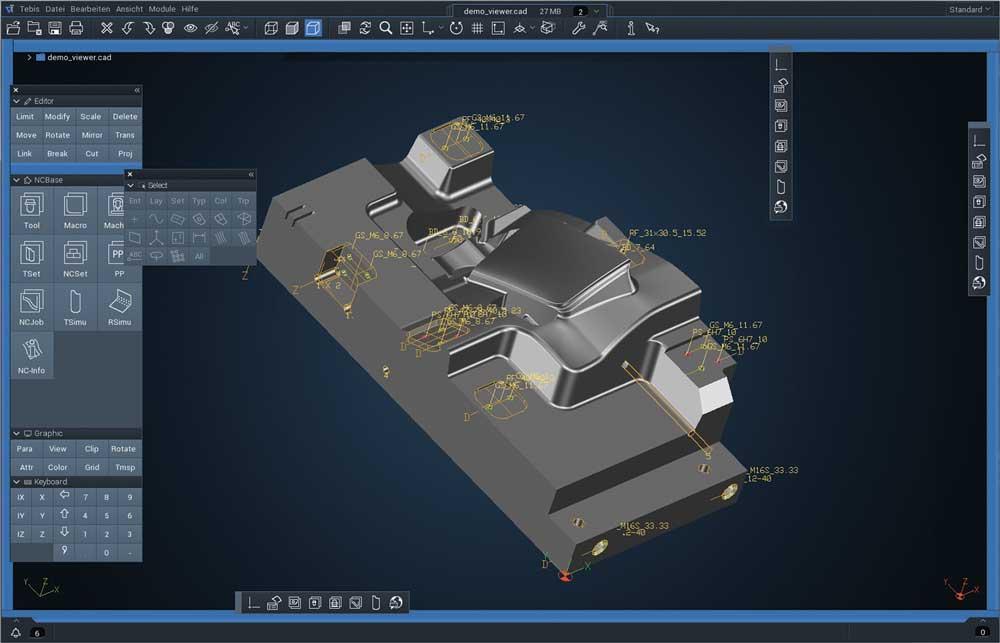

Trim line surfaces in draw die manufacturing.Ĭaption TEB-137B: Tebis Version 4.Crack download software EFI Fiery XF v6.5 Procon win 3.5 Roboguide v9.0 Hampson Russell Suite 10.3 pix4d v4.3 DNV Maros v9.3.1 milkpan86#- change '#' to Anything you need,You can als. Part surfaces in mold manufacturing as well as for trim steel and Surfaces at defined angles from any curves – this is ideal for separating Tebis now supports laser hardening and laser weld cladding affording an even larger range of applications.Ĭaption TEB-137A:A new function creates non-overlapping shifted With the new part-driven robotic machining, the robot can now guide a workpiece past a tool that is in a fixed position in the robot cell. It is important to permanently position the robot with the linear axes so that the arm is used within the optimal working area. For example, additional axes in robot cells can now also be controlled as simultaneous NC axes if the robot is mounted on a positioning unit. Tebis Version 4.0 Release 4 also offers new possibilities for robotic machining. This removes the residual stock at the end of the flank. The slope can be increased at the bottom of the pocket until the cutter tip (ball) exactly contacts the fillet between the flank and bottom. The slope can then be reduced to optimize tool wear. For these tools, which especially suitable for machining cavities, it is often better to first start with a slightly greater slope with a tool contact point that is closer to the cutter tip. When using barrel cutters, the tool contact point can now be better controlled according to the respective part situation. Options have been included for fast vector smoothing and for tilt-optimized calculation of toolpaths even without manual definition of vectors. The definition of toolpaths has been further simplified in 5-axis milling and operating convenience of the functions has been improved. This further simplifies automated deep-hole drilling based on the drilling information stored in the part. There is a new machining function that manages the special requirements of deep-hole drilling such as threading, intersections of bores or acceleration ramps. These values can be separately managed for each individual tool. There is also a new tool type with an extended set of cutting data and special speeds, feed rates, cooling types and depth sections needed for deep-hole drilling. If the active surfaces must be morphed to compensate for springback of the sheet, all trimming curves can be morphed, as well, to yield the geometries for a correctly trimmed sheet metal part in a single step.ĭeep-hole drilling in the CAM area has been better oriented to support automated calculation and machining. This results in benefits in draw die manufacturing, for example. Curves can now also be included in surface morphing. The geometry of the original curves is fully retained and color properties are transferred 1:1. In addition, parts can now be automatically morphed together with the most complex trimming curves in surface morphing.

As is usual for Tebis, the lengths and angles of surfaces can be conveniently and interactively adjusted using drag arrows. These surfaces are ideal for separating part surfaces in mold manufacturing as well as for trim steel and trim line surfaces in draw die manufacturing. All overlaps within parts that would result especially at sharp edges and small radii of curvature are automatically filtered out and smoothed. Design measures can thus be quickly implemented or new NC programs can be quickly calculated for modified areas.The new function creates non-overlapping shifted surfaces from any curves at defined angles.

With this new release, Tebis software creates area curves during part comparison to enable better detection and limitation of modified areas. Troy, MI, -Tebis America, a leading software company specializing in CAD/CAM systems for design and manufacturing servicing the tool, die, mold, automotive and aerospace manufacturing industries has announcedthe latest release 4 of its Version 4.0 Latest release includes many new and improved CAD and CAM functions that simplify work for die, model and mold manufacturers.

0 kommentar(er)

0 kommentar(er)